Wall mounting#

Step 1 – Unlocking the clock#

The frame is fixed using two suspensions (above) and two sliding springs (bottom). The frame is locked by frame catch from the bottom side of the frame.

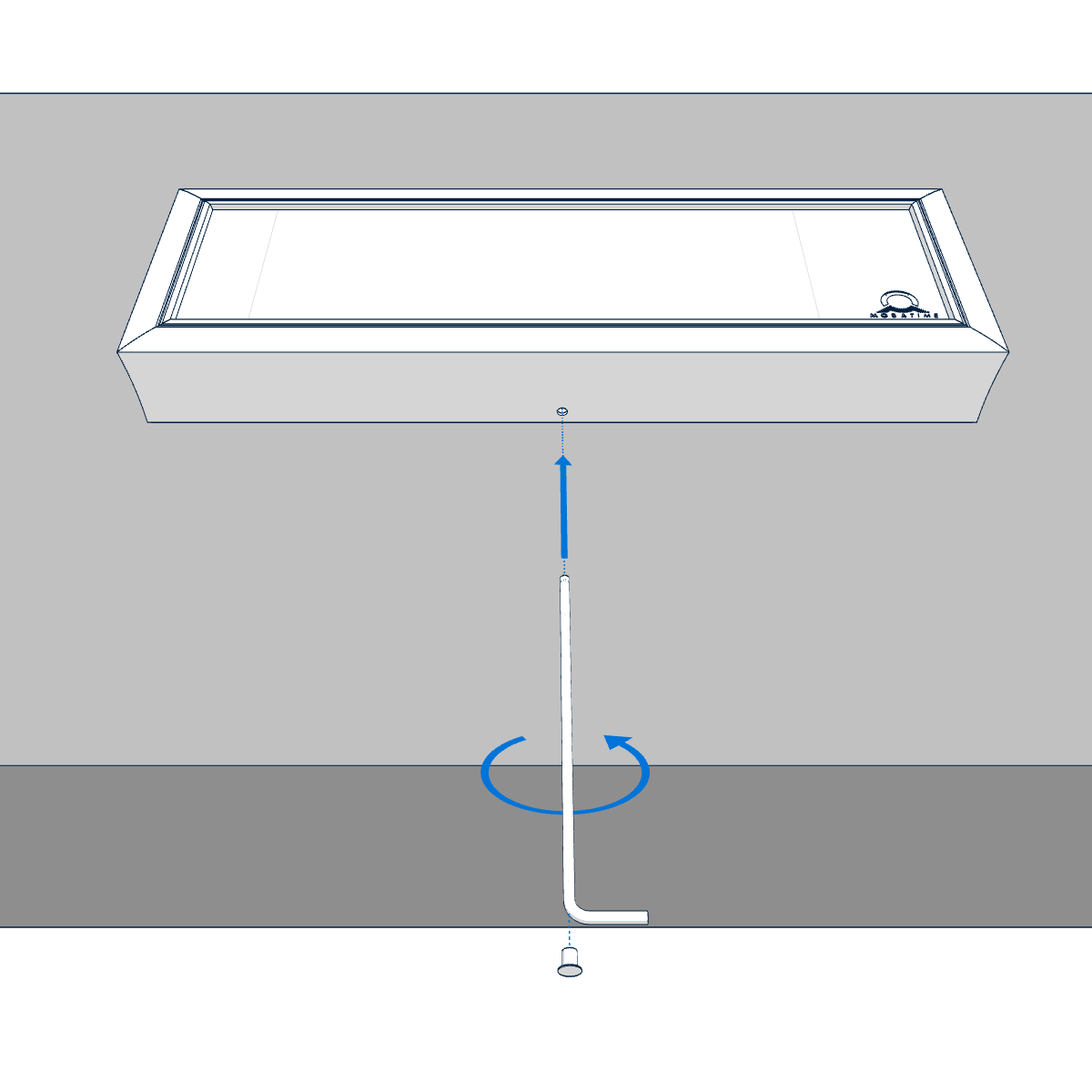

Remove the blind cap from the opening and insert the Allen key into the opening. Turn the key softly in clockwise direction to unlock the frame catch.

Note

Models DC with digit height 57, 75 and 100 the frame catch is unclocked (the screw is already screwed in) when the clock is delivered. The is no need to remove the blind cap and insert the Allen key.

Step 2 – Removing anchoring plate#

Lift‑off the anchoring plate using a screwdriver inserted in between the sheet and the frame at the sliding spring point on the clock bottom side.

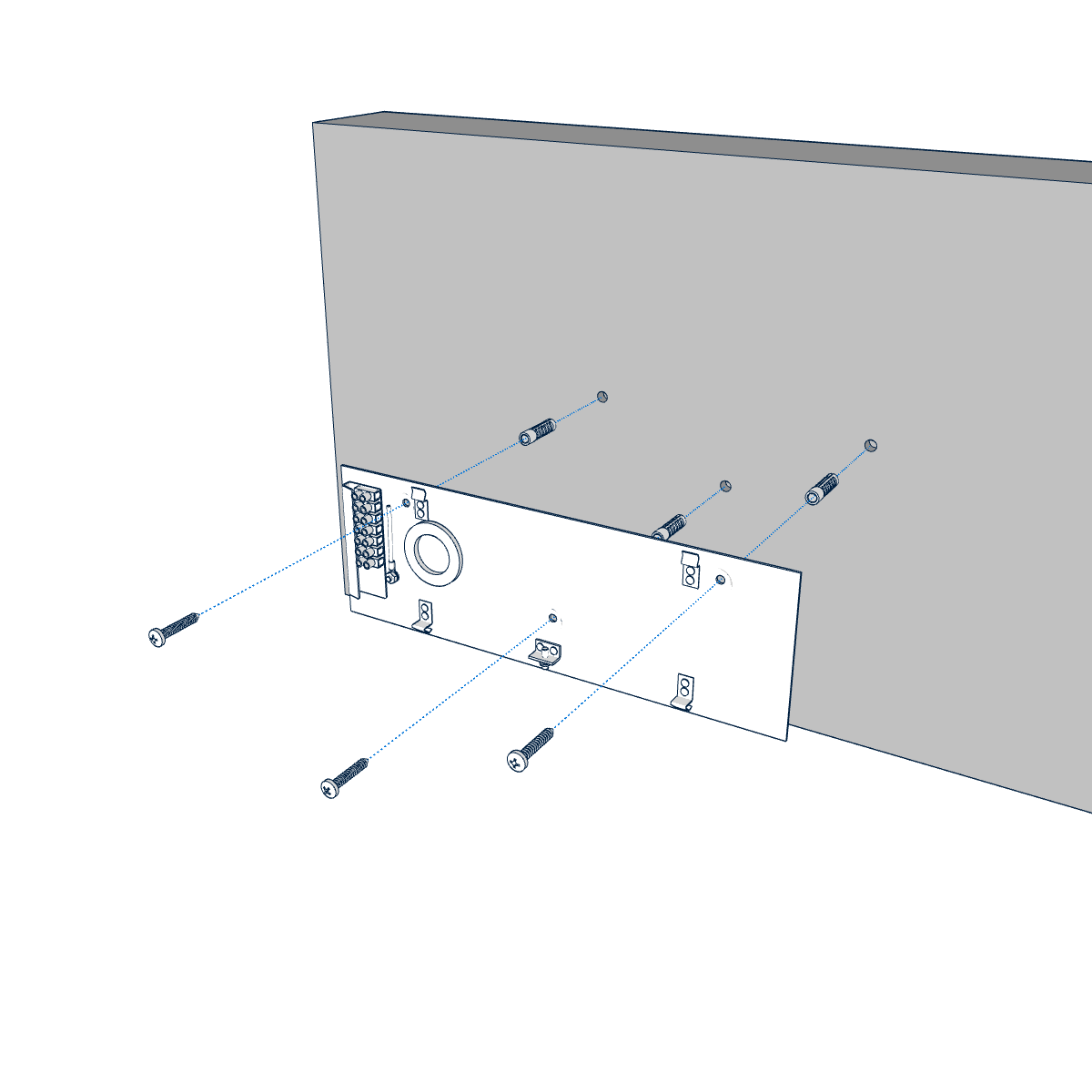

Step 3 – Fixing the anchoring plate#

Drill three anchoring holes into the wall of a diameter adequate to accommodate wood‑type screws of 4–5 mm diameter. As a template for marking the position of the holes the anchoring plate can be used.

Interlace the incoming conductors through the opening in the anchoring plate and fix the sheet to the wall.

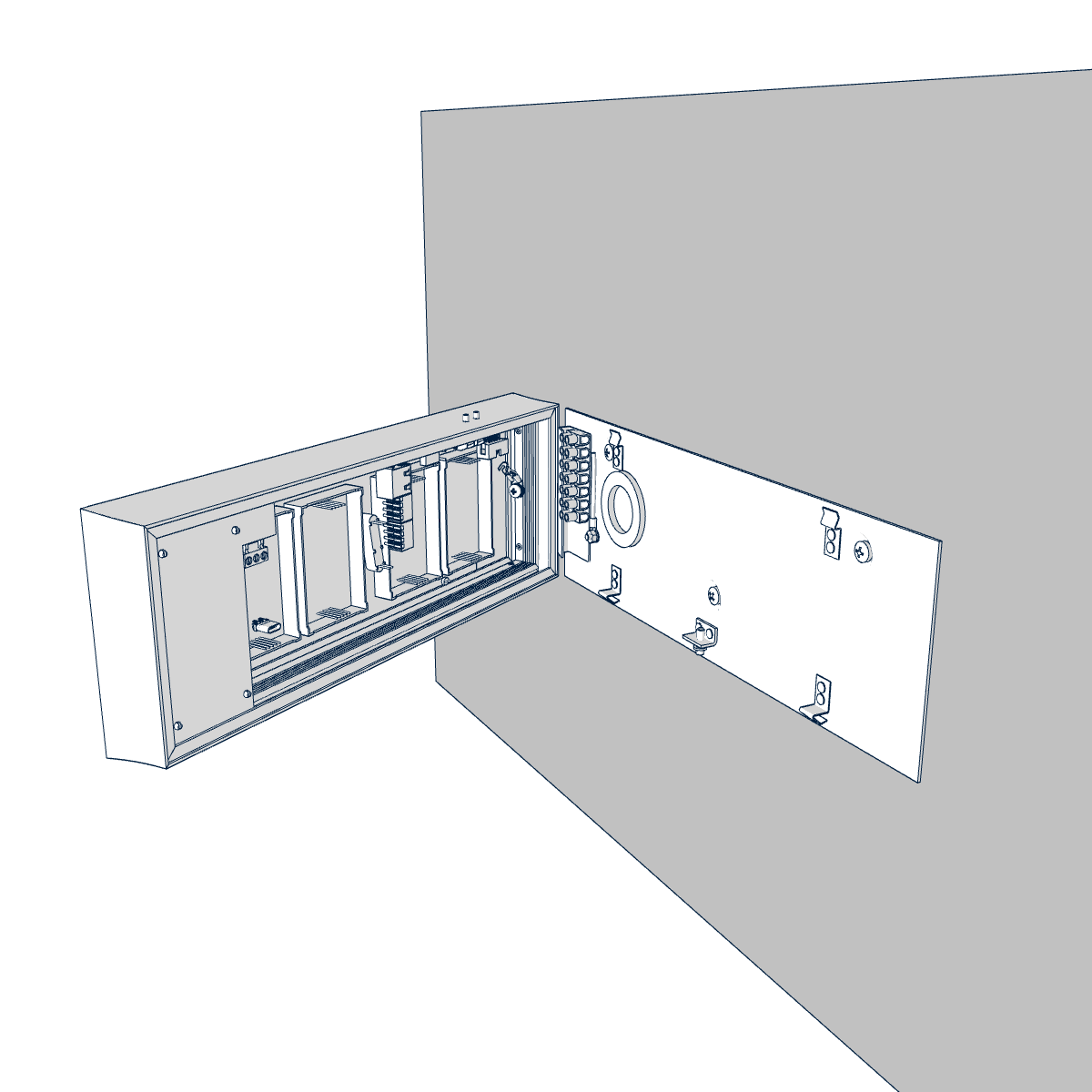

Step 4 – Connecting conductors & connectors#

Connect the incoming conductors in accordance with the descriptive sheet on the terminal board, placed on the anchoring plate. Give the conductors an appropriate shape or cut them off to a length that will not obstruct the placement of the clock onto the anchoring plate.

Caution

For LGC variant, configure the position of DIP switch according to used synchronization signal (applies only for DCF, MOBALine, polarized impulse line or IRIG‑B).

Navigate to Clock Operation chapter > Non-Network Clock Operation chapter to get detailed info about connection of various synchronization sources and receivers.

Mount the connectors to the cable of the temperature sensor, to the keyboard cable, Ethernet cable or to the RS-485 interface cable if these have been delivered.

Push the temperature sensor connector, the keyboard connector, Ethernet connector or the RS-485 jacks into the corresponding terminals on the control PCB.

Connect the interconnecting cables into the corresponding terminals on the clock control PCB.

Caution

Be careful not to swap terminals. Check the markings of the jack‑plugs.

See also

See cable connection chapter.

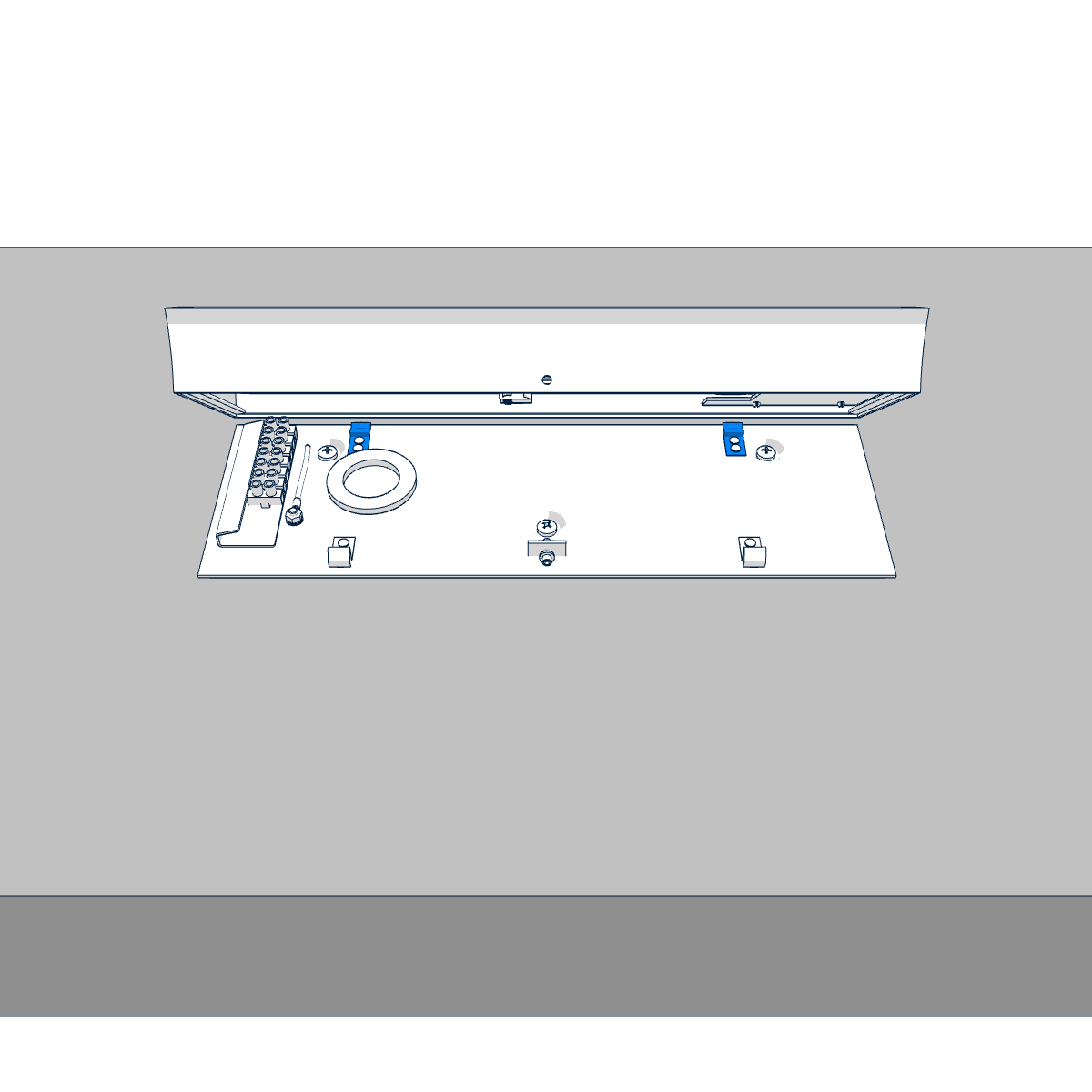

Step 5 – Suspending the clock onto the upper springs#

Put the clock opposite to the anchoring plate and suspend it onto the upper springs.

Caution

Care should be taken when placing the cables between the frame edge and the anchoring plate, so an not to nip them.

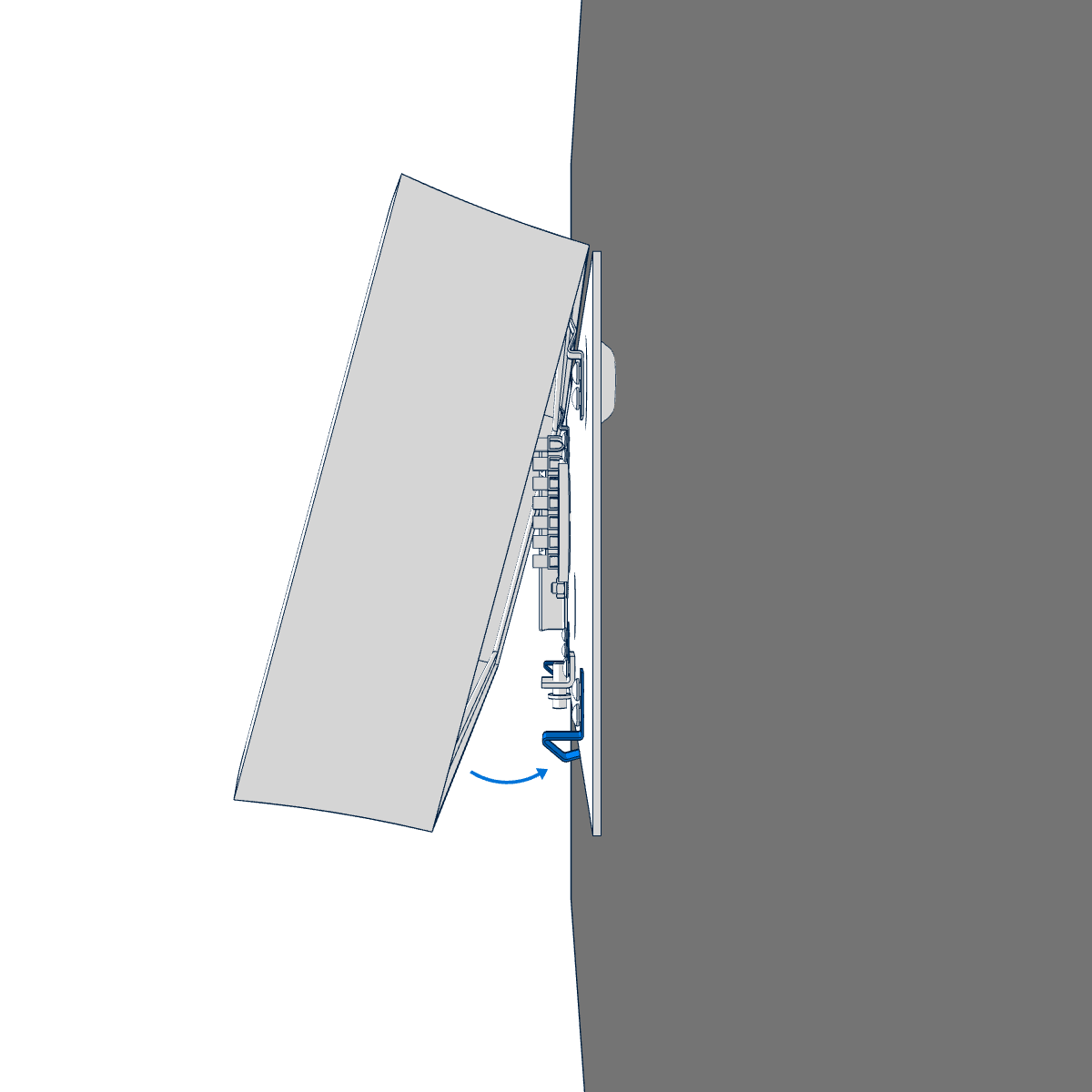

Step 6 – Snaping the clock onto the anchoring plate#

Snap the clock in onto the springs by pushing on the lower part of the frame.

Check whether the anchoring plate on the sides fits exactly into the groove in the clock frame.

Step 7 – Securing the clock#

Remove the blind cap from the opening on the clock bottom side.

Insert Allen key into the opening on the clock bottom side. Turn the key softly in anticlockwise direction. The frame catch will snap in.

Replace the blind cap on the opening.

To dismount the clock, use reverse procedure.